A global air-purifying manufacturer was unable to explore and take advantage of new digital opportunities due to its reliance on IT legacy systems. Bringing IT up to date through a cloud architecture design was imperative to safeguard the market position and help grow the business as part of the company’s digital transformation.

In brief

Challenge

The company’s existing IT solution was holding back innovation and production was not as efficient as it should be. Competitors were incorporating new functions and services in their products and deploying them much faster. As the market leader, the company had to act to secure their position, grow sales and modernize the entire product lifecycle.

Solution

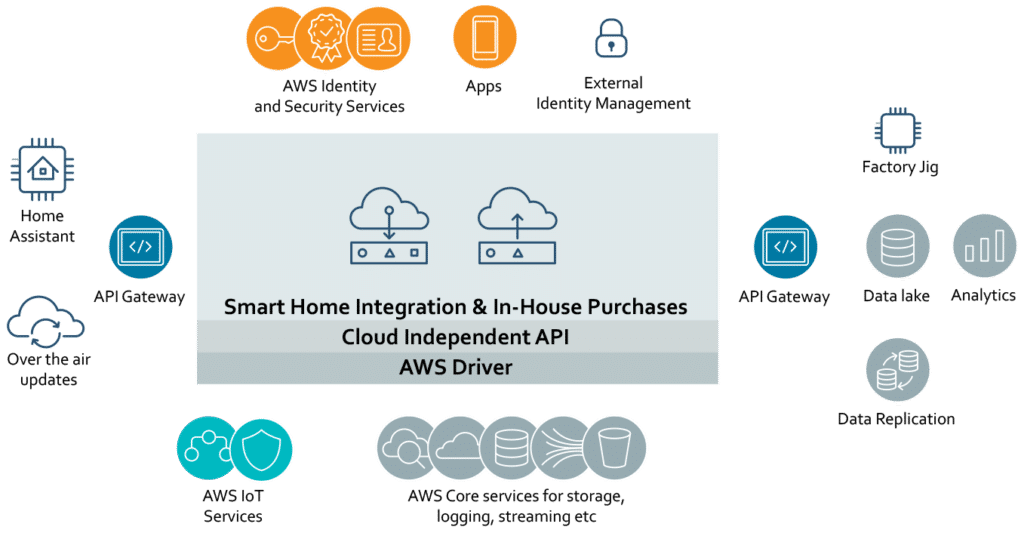

The new architecture design connects the entire ecosystem – from enterprise resource planning to user app control – in a secure, multi-cloud – AWS, Azure and Alibaba. It supports device management, online payments, real-time sensor monitoring, and advanced Business Intelligence tools.

How we did it

We worked closely with senior management at the company to define a digital roadmap. We designed the cloud architecture to support this and developed firmware in parallel to avoid delays in delivery.

Benefits

User data is now aggregated and analyzed to guide product development and improve the user experience through better app features and proactive air controls. Automated diagnostics enables issues to be fixed quickly online. Data security and integrity is assured. Additionally, manufacturing is more efficient, as automated processes have been incorporated into production.

About the client

The company is a global manufacturer and provider of air filter solutions for commercial and homeowner use.

Data-driven architecture design – from mobile apps and enterprise resource planning systems to data lakes and protocol adapters

A leading IT environment for a market leading company

As the leading provider of clean air products, the company’s solutions are renowned for their ability to filter air to provide protection against harmful pollutants. The company’s engineers are highly skilled in developing products that do this silently and effectively. However, they do not have the inhouse competence to develop an IT environment that can fully utilize the opportunities on offer from digitalization. Ductus was challenged with analyzing the company’s existing IT platform and designing a new, futureproof architecture that would put the company’s IT in the same leading spot as its market position.

“We were approached by senior management to look holistically at how IT is used today, analyze the potential opportunities IT can deliver, and develop a roadmap for the coming years. This included everything from giving users a first-class digital experience when using the product, to assessing how changes could be implemented in production, to creating a secure environment for sensitive user data.”

Mario Toffia, Ductus Senior Architect

A culture of user-centricity

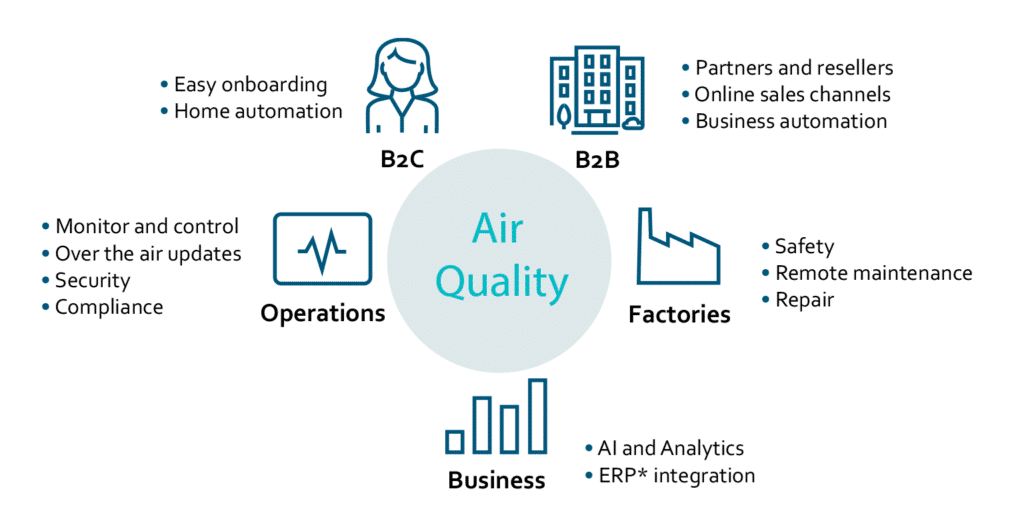

The assignment was run from a user-centric perspective. Providing clean air to businesses and consumers – in a simple and service-minded way – was the driving force of the cloud architecture design (see figure below). This meant developing a simple onboarding processes for end customers and identifying intelligent monitoring and analytics tools and processes to gain a better understanding of users, support predictive online maintenance and guide new product/feature development. Additionally, it covered the lifecycle of the product from supply of parts through to remote maintenance.

Holistic and fine-grained architecture

The team from Ductus – who worked closely with the client’s tech team throughout the assignment – consisted of a Senior Solution Architect, and a small development team with cloud, IoT and firmware expertise. The cloud architecture design included overreaching plans for how IT can support the business, all the way down to specifying protocol adapters, sensors, API gateways, identity management tools and much more (see figure below). The architecture design and specifications had to be comprehensive and intuitive in order for third-party utilization or indeed for another provider to deploy the service. Development of cloud functionality, APIs and firmware was also done iteratively and in parallel to the architecture design, so as not to slow the project down. This included everything from system development and testing, to device monitoring and control, to configuration and event management.

New product line

Due to the limited IT capabilities of existing products, the decision was taken to build a completely new “connected” line of products and an IoT platform to support them. This enabled monitoring of local air quality 24/7 from which push notifications could be sent to users and/or purifiers. With the new product line, much more data can be captured, providing more fine-grained data on user activity, such as why and how users adjust fan speed and the way in which they interact with the app. Regional user patterns can also be identified and analyzed.

Push notifications are used to engage users in the app to nudge them into using more product features and ultimately become more receptive to in-app campaigns.

Cutting-edge, cost-effective data management

“The system was designed to use two types of databases, one for events – since they are partially unstructured – and a time series database to capture telemetry bound to time, such as when air particles reach PM2.5 – the point at which a person’s health can be negatively impacted,” explains Toffia. “This provides a cost-effective way to run algorithms, and store, analyze and present data.”

The system design supports a configuration approach from which telemetry and events get pushed to the cloud. Fast analytics and machine learning tracks are done in real-time using Kinesis technology for streaming analytics. Batch processing is implemented via a data lake, whereby the data produced in the IoT cloud is exported to the data-lake every 15 minutes to reduce load and cost. The data is then analyzed and normalized using BI analytics and charting tools (including dashboards). Time constrained data is archived in slow to retrieve, low-cost storage.

Security

Security was paramount to the assignment. With much more user data being stored and analyzed, data integrity and compliance had to match capabilities. This challenge was compounded by the fact that users are located around the world, where differing regulations must be adhered to. To ensure customer data remains secure in the cloud – according to strict regulations – advanced certification, encryption and firewall services were incorporated.

Smoother and more secure production

The company wanted to open up its production processes to support a broader supply chain of air filters and purifiers as well as create a smoother flow between operations and production. To support this, enterprise resource planning systems were connected, and device provisioning was created for improved configuration and security. This system enables the secure production of units while prohibiting design theft or production of pirate filters and devices. This is central to the company’s multi-supplier model for filters, fans and other parts.

In conclusion

“By working closely with senior management and developers at the air filter company, we were able to achieve a great deal before the project was handed over” continues Toffia. “It was great to collaborate with an organization that is working to provide a better future for people through the air they breathe. The company was focused on end customers and ensuring they get the most out of air purifying solutions, but the IT structure didn’t match this. Not all companies have got so far in the journey of understanding that their IT system can be the key to delivering on customer expectations – but they had,” he concludes.