Machine vision for quality control

Inadequate quality control leads to product inconsistency, unhappy customers and can create bottlenecks in production. At many facilities, only a fraction of manufacturing output is submitted to quality control in order to save time and money. The majority of products go uninspected, even though supplying faulty products can be costly and hurt a business. Machine vision inspection changes this.

With an effective machine vision solution, every product in production can be inspected. Deviations can be detected and small variations can be identified at an early stage. This allows actions to be taken before quality drops below a required standard or quality problems occur further down the line.

Why machine vision?

Quality control often involves inspecting surfaces for defects as well as measuring dimensions and shapes, and the positioning of objects. Manual inspection tends to be operator dependent, and based on subjective evaluation. Measurements are quantitative, however, when performed manually they often lack precision, resolution, speed or reproducibility.

Without traceability, problems in production are hard to identify and amend/address. Quality control may be a simple pass or fail, but without proper documentation it is impossible to know why an article failed.

Quality control is desirable in all steps of production. However, there may be spatial constraints or safety concerns for manual inspection, making quick feedback impossible.

Machine vision in brief

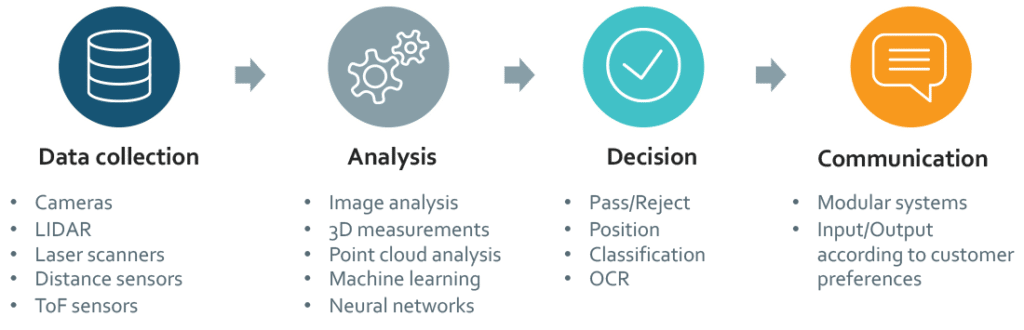

Computer aided cameras or other remote sensing techniques combine to solve an inspection task and deliver an appropriate prediction/decision.

Typical tasks that can be performed include:

- Detecting product defects, down to sub-millimeter sizes

- Deciphering blurred and unclear text

- Measuring and positioning with sub-millimeter precision

- Detecting, recognizing, and classifying objects and patterns

- Identifying issues in the production process i.e. predictive maintenance

Advantages with machine vision inpection:

- Compact – fits into confined spaces

- Reliable – consistent results 24/7

- Traceable – individual product results can be tracked and stored

- Speed – short cycle times enable inspection of every product

- High resolution – from hundreds to millions of measurement points

Collaboration – the key to successful machine vision implementations

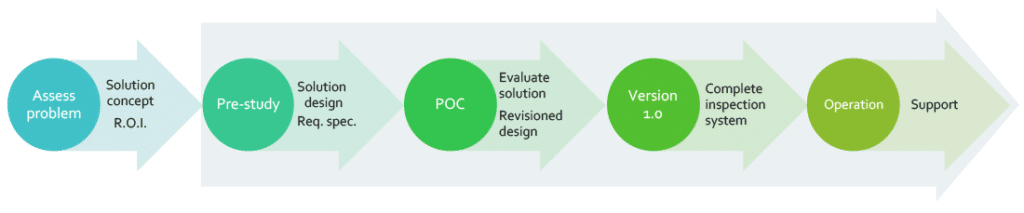

At Ductus we deliver tailored machine vision solutions that make a difference to quality control and ultimately improve production efficiency. We assess the unique conditions, requirements and quality control challenges in close collaboration with the customer. You are the expert in your field, with years of knowledge and experience, therefore your input is crucial for delivering the best possible solution. Based on this, we select suitable sensor techniques, find optimal locations for installation and integrate the solution into your infrastructure.

Carefully tailored solutions

With high-resolution cameras and properly placed illumination we can detect and position small defects to the submillimetre range. LIDARs, triangulating laser scanners and 3D-cameras enable us to capture 3D-data of objects and achieve measurements that are impossible to accomplish with callipers and rulers.

We are always exploring and evaluating new sensor techniques. In close collaboration with manufacturers, such as SICK, we push hardware to the limit.

State of the art toolbox

New sensors generate huge amounts of data that must be filtered, analyzed and stored in real-time. We use traditional digital image analysis combined with the latest in machine learning and neural networks to extract relevant information and make split second decisions. A solution can be implemented both on premise and in the cloud.

Customer use cases

Every installation and quality control challenge is unique. However, we have experience from diverse areas such as mining, paper production, space and biomedicine, and can adapt techniques from these and other areas to fit our customer’s needs. Below are just a few of our recently developed customer cases.

Defect detection in manufacturing

An aluminium parts manufacturer had multiple manual inspection stations in one of its production lines. These were replaced with a tailored machine vision inspection solution. A single camera now inspects the parts as they are displayed by a picking robot, at a rate of about 10,000 parts per day. Every part is now inspected and documented and costs are reduced.

Error detection in a processing plant

Stacking crates symmetrically is essential for picking robots. We provided a combined laser sensor and LIDAR solution which detects the height, pattern and orientation of crates to identify any stacking anomalies. This company can now run a fully automated warehouse. By replacing the manual stations, production times and costs have been considerably reduced.

Volume flow measurement in a busy mine

Our machine vision solution is used to measure the flow of finely crushed iron ore and identify large rocks and debris in an extremely harsh environment. Based on the data gathered by a sturdy LIDAR 3D scanner on a conveyer belt, processes are monitored, and very costly damage and production hold-ups caused by debris are avoided.

Predicting quality of aluminium wire bonds

A wedge bonder is used to attach aluminium wires to the surfaces of components at an automotive power module and semiconductor manufacturer. The wedge bonder uses ultrasound to vibrate a wire until it fuses with the surface. The strength of the bond depends on the frequency and pressure applied by the wedge bonder. By analysing images and process parameters for over 8 million bonds, we built a model that accurately predicts the strength of the bond and suggests possible causes of error for any bonds that fail strength requirements.

Advisory services

Advisory services

We offer a range of services for manufacturers and suppliers that are investigating the benefits of machine vision or for those who wish to get more from their existing solutions. These include:

- Workshops on machine vision inspecton and the potential benefits for an existing production process

- Workshops on machine vision inspection and potential benefits for a new production process

- Analysis of an existing machine vision implementation and recommendations for improvements

Nils-Erik Olofsson

Phone: +46 920 28 81 55

nils-erik.olofsson(at)ductus.se