Operators at Inpac were struggling to simultaneously fill, quality check and pack bottles during production. The two production lines fill, cap, and label 125 bottles each per minute. With several thousand bottles passing down the line every hour at breakneck speed, small faults were going undetected. Ductus was contacted to develop an autonomous detection system to solve this.

In brief

Challenge

Help Inpac ensure they only ship bottles that are filled to the right level with the caps screwed on properly and with correctly attached labels that have a clearly visible date stamp.

Solution

Cameras inspect a bottle in its entirety and lighting enhances the appearance of any present defects. Custom-software analyzes images and signals an ejector when a faulty bottle is detected.

How we did it

Together with Inpac, we designed, developed and deployed a unique solution to fit the bottling lines. This included designing image analysis algorithms to detect and reject faults and training AI to recognize the different parameters.

Benefits

Thanks to the autonomous detection system, Inpac has drastically improved the output quality of the production lines. A Human-Machine Interface, HMI, alerts operators when something is amiss in production, effectively reducing wastage and increasing efficiency.

About the client

Inpac provides packaging solutions for pharmaceutics, probiotics, dietary health, and nutritional supplements. In addition, they are also a manufacturer and supplier of health and nutritional supplements. The company is privately owned and headquartered in Lund, Sweden.

Identifying a need

Inpac fills and packages large quantities of bottles every day, which are then distributed worldwide. Each customer has their own quality requirements and expectations of the delivered product. What is considered a minor flaw by some, might be a deal breaker for others. Thus, high quality at delivery is critical to minimize complaints and maximize customer satisfaction. This begins with quality on the two production lines.

Prior to the project, there wasn’t a dedicated quality inspection process in place. Instead, operators did their best to inspect the bottles when packing them. With a production rate of 125 bottles a minute per line, this was very challenging. Defects were, unsurprisingly, being packed and delivered. Inpac identified this as a weak link in their quality assurance process and turned to Ductus for help to solve the issue.

Finding a solution

One key factor in designing an effective autonomous detection solution was the close collaboration between Ductus and Inpac. Combining Inpac’s process expertise and Data Ductus’s machine vision expertise, streamlined the entire assignment. It all started with a site visit, to clarify the conditions and any constraints.

As a first step, a requirement specification was composed and agreed upon. A well-formulated requirement specification is crucial as, in the case of Inpac, it describes the scope and the prerequisites of the system, and specifies the characteristics defining a faulty bottle. Based on this, we were able to propose a custom-made system, which we then designed to meet the unique requirements of the products and production lines.

Implementing the autonomous detection solution

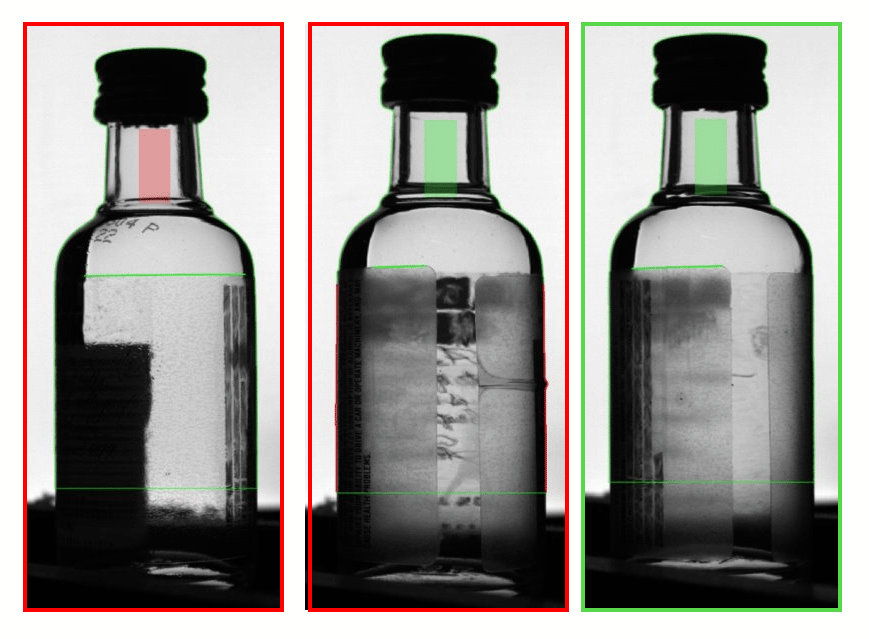

The solution consists of carefully chosen hardware in conjunction with software and analysis tools developed by Data Ductus. Three cameras and two panel lights, placed at a specific geometry, ensure that all present errors are visible in the captured images. When a faulty bottle is detected, this is signaled to an ejector, which removes the bottle from the conveyor belt.

The image analysis algorithms are designed to measure label position and filling level, and detect defects such as label creases and caps that are not properly screwed on. To adjust the sensitivity of the algorithm, so only faulty bottles are rejected, several parameters had to be tuned. If batches or baseline specifications change, AI methods can be used to find optimal parameter sets based on training data of correct and faulty bottles.

Ensuring stable operation

With an hour of downtime corresponding to 15,000 bottles, Ductus offers a wide range of cost-effective support agreements. Diagnostics and planned maintenance can be performed with remote access to the autonomous detection system. Most incidents can be resolved remotely by analyzing error logs and collected data. In some cases, on-site operators can get guidance to solve an issue. If hardware has been damaged, replacement may require on-site visits.

Enjoying the benefits

Machine vision systems collect a lot of valuable information from production lines. We compile statistics from the bottling process and present them in an easily accessible graphical user interface. This allows Inpac to better understand their production line and identify bottlenecks or detect irregularities before they impact the quality of production.